91 at extrusion speeds 200 mmin. Tube with an Outer Diameter OD of 50 mm.

Ldpe Blown Film Waxs As A Function Of Their Draw Down Ratio And Corres Download Scientific Diagram

If deckles are used the internal flow channels should be streamlined so there is no stagnant TPU that would result in degradation.

. This difference may be desirable in tear tapes or strapping but unwanted if it reduces impact strength or shrinks differentially when cooling. But in practice the extrudate swell is smaller than the equilibrium value and some pulling is needed. Typically a horizontal or vertical extrusion hydraulic press is made of container die die holder ram press plate and.

The extrusion-coating process is illustrated in Figure 5. For the first series of blown films in which the draw-down ratio was increased from 19 to 79 for a constant blow-up ratio of 168 the a axis was observed to increase its orientation along the. The draw-down is the ability of the melt to be drawn to thin films without breaking.

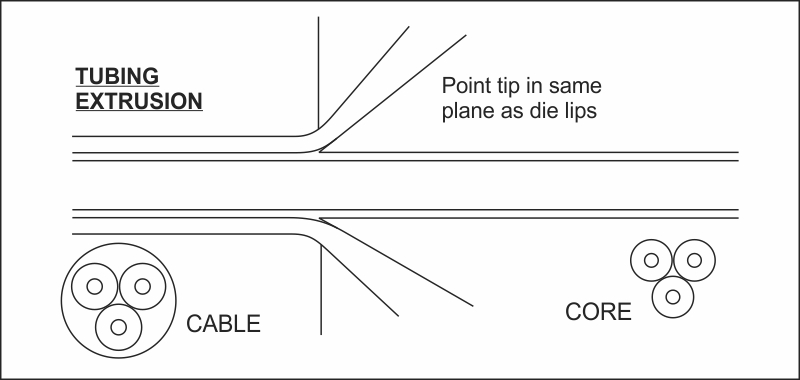

This is normally used when performing a tubing extrusion where the cable is. TPU pellets are compacted and fluxed in the. 2 45 DDR draw down ratio gap widththickness x BuR MD machine direction TD transverse direction LD ratio of screw.

Extrusion Tooling Tips Dies. Plastic melt to the cross sectional area of the plastic in its final product form be it a tube hose or insulation on a core such as a wire or cable. The DDR is the ratio of the annular toolset exit area bushing ID area minus mandrel OD area divided by the final product area OD area minus ID area.

DD Diameter of Extrusion Die DT Outside Diameter of Tip PD Product Diameter CD Core Diameter The Draw Down Ratio DDR is calculated by comparing the cross sectional area of the extrusion. Extrusion Parameters Parameters include die angle a extrusion speed billet temperature and lubrication Extrusion ratio R A o A f typical values of 10 to 100 Circumscribing Diameter CCD for Aluminum 6 mm to 1 m for steel up to 015 m Shape factor PerimeterCCD Extrusion constant k Typical lengths 75 m. In extrusion there is always a machine direction and anisotropy shows up as MDTD difference or ratio in the final product in tensile strength elongation to yield andor modulus rigidity.

Plastic processing forums for extrusion information and advice and for other feed screw applications. 9 Frombrazil IN USA Registered. Some express that it needs a wide range of talent on portray your personal nails.

Simply provide these four values and calculate. Guill Tool Engineerings Tips and Dies are manufactured with precision unmatched in the industry today. Shawn8791 Senior Member.

Draw down ratio in extrusion For a starter you may make your very own Nail Art Result utilizing two strategies. Area draw down ratio is the ratio of the cross-sectional area of the extruded plastic melt to the cross sectional area of the plastic in its final. Both solid billet and hollow tube can be produced by extrusion.

In absence of a pulling force on the profile the ratio Lambda should approach 1. The calculators below allow you to calculate DDR draw Down Ratio and DBR Draw Balance Ratios for a given Tip Outer Diameter OD Die Outer Diameter OD and finished product OD and ID Inner Diameter. Posted February 01 2008 1229 AM.

To keep the drawdown to a minimum. The subscript z refers to the diameter measured optically at a distance z from the die exit. Use lower draw-down ratio Reduce extrusion rate Extrusion OD too low Reduce haul off speed Change to smaller die run with slight die swell Improper filling of the die Use smaller size die Porosity Compound wet Vacuum dry replace material Colour master batches wet Vacuum dry replace material Melt temperatire too high.

BUR blow up ratio. I currently extrude PE on a single screw extruder and use a Draw Down Ratio of 2 for tube covers and 339 for tube linersIDs range approx 63mm to. The neck-in is the reduction of the film width and may cause uncoated areas on the substrate.

Extrusion process control that are simple to apply and virtually foolproof. Along with modifying polymer properties choosing the appropriate draw down ratio is also vital to process stability. Another guide for setting uniformity and best repeatable references is the draw ratio balance DRB that aids in determining the minimum and maximum values that can be used for different plastics.

This can also be referred to as the area draw ratio ADR. For a tube this is calculated by the following formula. DDR DD2 DT2PD2 CD2 The Draw Ratio Balance DRB is the balance between.

The high quality of our extrusion tooling enables your company to output the highest quality product. The rheology-related phenomena that may cause problems in extrusion coating are neck-in NI and draw-down DD. Extrusion ratio initial cross sectional area final cross sectional area is a measure of magnitude of plastic deformation introduced to the billet 49.

Two of the most important calculations are area draw down ratio ADDR and draw ratio balance DRB. Draw Down Ratio In Extrusion. Draw down ratio DDR cross section of die divided by cross section of tube.

Drawn Down Ratio Two ways to calculate DDR Vf Vo V f 805 cms V o 664 cms DDR 121 European style DDR die gap film thickness BUR Die Diameter 250 mm 25 cm Die Gap 60 mil 0152 cm BUR 25 DDR 152 NA style Calculate DDR Die V o V f. 121 to 151 Draw ratio balance DBR ratio of die to mandrel diameter divided by ratio of outer to inner diameter of tubing. Two important calculations involve the draw down ratio DDR and the draw ratio balance DRB.

This should be 20 to 1 or less. The Draw Down Ratio is the ratio between the area between the die opening and the external diameter of the tip. Obtaining 3D decorations constructed from plastic and glue them on the nail or you will get your personal acrylic and paint your own private nails.

The neck-in is less if the melt elasticity is high. Draw-down ratio DDR in a circular die such as a wire die is the ratio of the cross sectional area of the die orificeopening to the final extruded shape. After using the Draw Down Calculator below you can Request a Quotation or contact Guill to discuss how.

Draw Down Ratio is the ratio of the cross sectional area of the extruded. 8 rows Draw Down Ratio.

Draw Ratio Balance Big Chemical Encyclopedia

The Effects Of Blow Up Ratio A And Draw Down Ratio B To The Download Scientific Diagram

Fundamentals Of Extrusion Technology Wire Cable India

Drawdown Ratio Big Chemical Encyclopedia

Ldpe Blown Film Waxs As A Function Of Their Draw Down Ratio And Corres Download Scientific Diagram

0 comments

Post a Comment